Description

The Ultimate Guide to CNC Bus Assembly Equipment for Bus Frame

Immerse yourself in the fascinating world of CNC Bus Assembly Equipment for Bus Frame. Uncover insights from industry professionals and discover how these machines revolutionize the bus manufacturing industry.

Introduction

Today's modern buses are engineering marvels, using sophisticated techniques and technologies to ensure their safety, efficiency, and reliability. One essential part of this production process is creating the bus frame - a vital component that forms the vehicle's skeleton. And what's at the heart of this manufacturing feat? It's none other than the CNC Bus Assembly Equipment for Bus Frame, an advanced machinery that redefines the standards of bus production.

CNC Bus Assembly Equipment for Bus Frame: The Game Changer

When it comes to bus manufacturing, nothing does it better than Computer Numerical Control (CNC) technology. CNC Bus Assembly Equipment for Bus Frame has altered the industry landscape, providing precision, speed, and consistency that manual methods could hardly match. What makes CNC technology the go-to choice in bus frame assembly? Let's dive into the specifics.

Unparalleled Precision

Accuracy is the game's name for the bus frame assembly. WITH ITS COMPUTERIZED MECHANISM, the CNC Bus Assembly Equipment for Bus Frame can create detailed and intricate bus frames with unparalleled precision. The numeric system allows for complicated and complex designs, often down to fractions of millimeters - a feat impossible to achieve manually.

Enhanced Speed and Efficiency

In the competitive world of bus manufacturing, time is money. CNC technology offers increased speed and efficiency, thereby accelerating the production process. It eliminates manual labor, enabling multiple tasks to be accomplished simultaneously. Bus manufacturers can effectively meet growing demands with faster turn-around times without compromising quality.

Consistency and Quality Control

In bus frame assembly, consistency is paramount. The CNC Bus Assembly Equipment for Bus Frame ensures that every bus frame produced adheres to the same high standards of quality and design. This uniformity reduces the margin for error and ensures that each bus frame leaving the assembly line meets the rigorous standards set by the industry.

Flexibility in Design

Innovation is critical in bus manufacturing. CNC Bus Assembly Equipment for Bus Frame offers flexibility in design, allowing manufacturers to experiment with different bus frame structures and styles. It enables the production of custom-made bus frames based on specific customer requirements, ushering in a new era of customization in the bus manufacturing industry.

The Making of a Bus Frame: The Role of CNC Bus Assembly Equipment

The assembly of a bus frame is a multi-step process, with the CNC Bus Assembly Equipment for Bus Frame playing a crucial role in each stage. This versatile machine is at the heart of everything from cutting and drilling to welding and final assembly. Let's look at each of these steps in detail.

Cutting and Drilling

CNC Bus Assembly Equipment is responsible for precisely cutting and drilling individual frame components. It uses computerized calculations to determine the exact dimensions and positions for each cut and drill hole, ensuring perfect alignment for subsequent assembly.

Welding

Welding forms a crucial part of the bus frame assembly, connecting the different parts of the frame. CNC equipment ensures precise, high-quality welds that contribute to the strength and durability of the bus frame.

Final Assembly

In the final assembly, the components come together to form the complete bus frame. CNC technology ensures that each part fits perfectly into place, resulting in a well-structured, solid bus frame that stands the test of time.

Incorporating CNC Bus Assembly Equipment for Bus Frames in Your Business

If you're in the bus manufacturing industry, investing in CNC Bus Assembly Equipment for Bus Frames could be a game-changing move. However, integrating such advanced machinery into your business requires careful consideration. Here's what you need to think about.

Assessing Your Business Needs

Before investing in CNC technology, assessing your business needs is crucial. The type, size, and scope of your bus manufacturing operations will determine the kind of CNC Bus Assembly Equipment for Bus Frame that's suitable for your business.

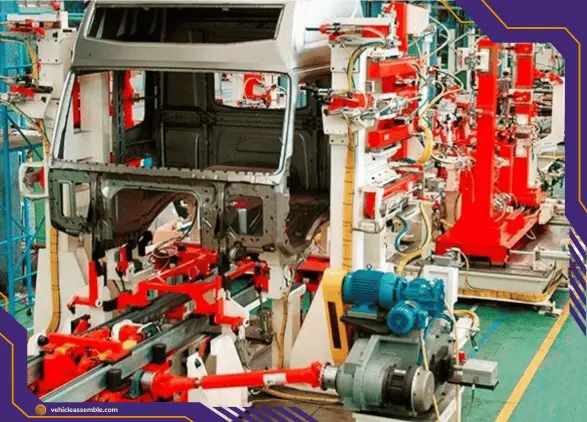

Equipment Description

This is a CNC Assembly Machine for Bus Frames dedicatedly designed and developed by our company in response to the requirements for lightweight new energy and the all-aluminum frame technology of mainstream Chinese bus manufacturers. It can position and secure the left and right side frames, top frames, and floor frames to ensure the welding or riveting precision of the connection of structures.

Equipment Configuration

Twelve meters long, grid module structure used for window pillar positioning, easy to operate near the bus body.

Optional

Computer Numerical Control drilling system(automatically locates and drills holes for connecting the left and right side frames to the floor frame, reducing workers' labor intensity and improving the production efficiency of all-aluminum bus frames).

Choosing the Right CNC Bus Assembly Equipment for Bus Frame

Choosing the right one can be daunting with various CNC machines. Size, precision, speed, versatility, and cost should all be considered before deciding.

Training Your Staff

Integrating CNC technology into your operations involves more than just buying the equipment. Your staff needs to be adequately trained to operate the CNC Bus Assembly Equipment for Bus Frame, which could include time and resources.

Maintaining Your CNC Bus Assembly Equipment for Bus Frame

Like any other machinery, the CNC Bus Assembly Equipment for Bus Frame requires regular maintenance to ensure longevity and efficiency. Make sure to incorporate a robust maintenance schedule into your operations to keep your CNC machine running smoothly.

Future of Bus Frame Assembly: CNC Bus Assembly Equipment for Bus Frame

The CNC Bus Assembly Equipment for Bus Frame is more than a passing trend. It represents a fundamental shift in how bus frames are made and is here to stay. As technology evolves, we expect even more exciting developments in bus frame assembly.

Increasing Automation

As the world continues to embrace automation, we can expect to see CNC technology becoming even more prevalent in bus frame assembly. More processes will be automated, resulting in even greater efficiency and precision.

Integration with AI and Machine Learning

Integrating Artificial Intelligence (AI) and Machine Learning (ML) with CNC technology presents exciting possibilities. These advancements could lead to more innovative CNC machines that can learn and adapt, further improving the quality and efficiency of bus frame assembly.

FAQs

What is CNC Bus Assembly Equipment for Bus Frame?

CNC Bus Assembly Equipment for Bus Frames is a machine used in bus manufacturing that uses Computer Numerical Control (CNC) technology to assemble bus frames precisely.

Why is the CNC Bus Assembly Equipment for Bus Frames important in manufacturing?

CNC technology offers unparalleled precision, efficiency, and consistency in bus frame assembly. It also allows for design flexibility, making it an essential tool in bus manufacturing.

How does CNC Bus Assembly Equipment for Bus Framework?

CNC Bus Assembly Equipment uses computerized controls to cut, drill, weld, and assemble the various components of a bus frame. The result is a high-quality, precision-engineered bus frame.

What are the key factors when investing in CNC Bus Assembly Equipment for Bus Frame?

Key factors to consider include the type and scope of your bus manufacturing operations, the size, precision, speed, and versatility of the CNC machine, the training requirements for your staff, and the maintenance of the equipment.

What is the future of bus frame assembly with CNC Bus Assembly Equipment for Bus Frame?

The future with increasing automation and AI and Machine Learning integration with CNC technology looks promising. This will lead to more intelligent, efficient, and adaptable bus frame assembly processes.

Conclusion

The CNC Bus Assembly Equipment for Bus Frames represents the future of bus manufacturing. It offers precision, efficiency, and consistency that surpasses traditional methods, promising a new era of quality and innovation in the industry. By understanding its workings and potential, businesses can leverage this powerful tool to take their bus manufacturing operations to the next level.