Description

The Indispensable Tool in Car Assembly Line: Top-Side Skin Arc Bending Machine

Explore the intricate and transformative world of the Top-Side Skin Arc Bending Machine, an essential piece of equipment in the car assembly line. Learn about its mechanics, benefits, usage, and pivotal role in automotive production.

Introduction

In the automotive industry, efficiency, precision, and speed are paramount. Achieving this trifecta of performance is only made possible through sophisticated machinery, and one such crucial device is the Top-Side Skin Arc Bending Machine. This innovative machine plays a pivotal role in car assembly lines, streamlining the production process and ensuring the seamless production of high-quality vehicles. Buckle up as we delve into the specifics of this powerful tool and unravel its indispensable role in the automotive world.

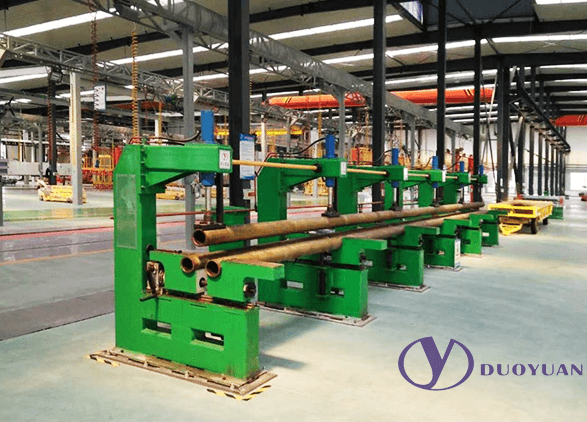

The Backbone of the Car Assembly Line: Top-Side Skin Arc Bending Machine

The Top-Side Skin Arc Bending Machine is the unsung hero of the automotive manufacturing process. Serving as a backbone in the car assembly line, it is primarily responsible for shaping the top-side skin of vehicles. Without this, the perfect arcs and curves you see on the tops of cars would not be possible. But what's the science behind this remarkable machine? Let's dive into the mechanics.

Mechanics of Top-Side Skin Arc Bending Machine

Under the hood of the Top-Side Skin Arc Bending Machine lies a complex array of mechanical components. It operates on the principles of mechanics and bending, transforming a flat sheet of metal into the top-side skin of a car with an exquisite arc. It does this through specific movements and adjustments, demonstrating an impressive combination of power and precision.

Hydraulic System

The hydraulic system is the heart of the Top-Side Skin Arc Bending Machine. It's responsible for supplying the necessary force to shape the metal sheets. The intricate play of hydraulics allows the machine to exert colossal pressure on the metal sheets, initiating the bending process.

CNC Control System

The Computer Numerical Control (CNC) system is the machine's brain. It orchestrates every action, dictating the precise movements necessary to create the perfect arc. This automated system ensures consistency in the production line, significantly reducing human error.

Benefits of Using a Top-Side Skin Arc Bending Machine

The Top-Side Skin Arc Bending Machine offers numerous advantages, making it an invaluable asset in the car assembly line. Let's explore some of these benefits in detail.

Enhanced Precision

With the help of the CNC system, the Top-Side Skin Arc Bending Machine guarantees unparalleled precision. Every arc produced is uniform, ensuring car tops' consistent, high-quality production.

Increased Efficiency

The automation offered by the Top-Side Skin Arc Bending Machine results in increased efficiency. This machine eliminates the need for manual labor in shaping the top-side skin of cars, saving time and energy, and accelerating the production process.

Reduced Wastage

Due to its precision, the Top-Side Skin Arc Bending Machine significantly reduces the wastage of metal sheets. Every cut and bend is exact, resulting in minimal leftover material.

Incorporating the Top-Side Skin Arc Bending Machine in Your Assembly Line

Now that we've covered the mechanics and benefits of the Top-Side Skin Arc Bending Machine let's talk about how to incorporate it into your assembly line.

Understanding Your Needs

Before incorporating the machine, it's crucial to understand your production needs. Assessing your production volume, desired efficiency, and quality standards can help you decide if the Top-Side Skin Arc Bending Machine is the right fit.

Choosing the Right Model

There are various Top-Side Skin Arc Bending Machine models, each with unique features. Careful consideration of capacity, speed, and accuracy will guide you in selecting the suitable model.

Training Your Staff

After selecting and installing the machine, staff training becomes a crucial step. Although the device is automated, understanding its workings ensures optimal use and maintenance.

FAQs

How does a Top-Side Skin Arc Bending Machine work?

The machine operates on the principles of mechanics and bending, using a hydraulic system and a CNC system to shape the metal sheets into the top-side skin of a car.

What are the benefits of using a Top-Side Skin Arc Bending Machine in a car assembly line?

It offers several benefits, such as enhanced precision, increased efficiency, and reduced wastage.

What should I consider when incorporating a Top-Side Skin Arc Bending Machine into my assembly line?

You should understand your production needs, choose the suitable model of the machine, and provide adequate training to your staff.

What role does the CNC system play in the Top-Side Skin Arc Bending Machine?

The CNC system orchestrates every action, ensuring the precise movements necessary to create the perfect arc and consistency in the production line.

How does the Top-Side Skin Arc Bending Machine increase efficiency in a car assembly line?

By automating the shaping of the top-side skin of cars, the machine saves time and energy, thereby increasing efficiency.

What is the role of the hydraulic system in a Top-Side Skin Arc Bending Machine?

The hydraulic system supplies the necessary force to shape the metal sheets, exerting colossal pressure to initiate the bending process.

Conclusion

The Top-Side Skin Arc Bending Machine has revolutionized car assembly lines, making it a must-have for any automotive production process. Its ability to deliver high precision, increased efficiency, and reduced wastage makes it an essential tool in the industry.