Description

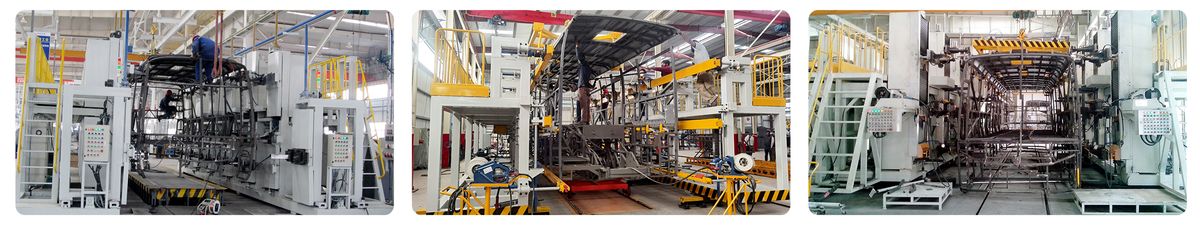

CNC Side Skin Roll Forming Equipment: A Revolutionary Tool in the Car Assembly Line

Dive deep into the mechanics, applications, and innovations of the CNC Side Skin Roll Forming Equipment about car assembly lines. Discover how it's redefining automotive production.

Introduction

Precision and efficiency reign supreme in the intricate world of car assembly lines. CNC Side Skin Roll Forming Equipment is not just another addition to this complex system. Instead, it stands out as a pivotal instrument, driving modernization and ensuring seamless integration of various components in vehicle manufacturing. But what is it? And why is it garnering so much attention in the automotive industry? Let’s get under the hood and discover the magic of CNC Side Skin Roll Forming Equipment.

CNC Side Skin Roll Forming Equipment: An Overview

Roll forming has long been an integral part of the automotive manufacturing process. But with the advent of CNC (Computer Numerical Control) technology, this process has been elevated to new heights. The CNC Side Skin Roll Forming Equipment specifically addresses the need for high precision when shaping the side panels or "skins" of vehicles.

The Mechanics Behind It

Traditional roll forming vs. CNC roll forming: CNC offers greater accuracy and flexibility. With computer-aided design and execution, manufacturers can produce consistent, high-quality results.

Application in Car Assembly Lines

This equipment isn’t just about rolling metal; it’s about crafting perfection. It ensures the side skins of vehicles have uniformity, which is crucial for aerodynamics, aesthetics, and overall structural integrity.

Key Innovations and Technological Advancements

This equipment isn’t just about rolling metal; it’s about crafting perfection. It ensures the side skins of vehicles have uniformity, which is crucial for aerodynamics, aesthetics, and overall structural integrity.

Benefits of Integrating CNC Side Skin Roll Forming Equipment

Consistency is King: Every piece produced is a mirror image of the last, ensuring that every vehicle component fits perfectly.

Speed and Efficiency: Time is money, especially in car manufacturing. CNC equipment streamlines processes, resulting in quicker production times.

Cost Savings in the Long Run: While the initial investment might be substantial, the long-term benefits of reduced wastage, fewer errors, and decreased manual labor cannot be ignored.

Real-World Applications and Case Studies

Adoption by Major Car Manufacturers

Big players in the automotive industry have already integrated CNC roll forming into their assembly lines. Companies such as Toyota and BMW swear by its efficacy.

Customization and Special Projects

Beyond mass production, CNC roll-forming equipment shines in producing customized parts for limited-edition vehicles or special projects.

Challenges Faced and Overcoming Them

High Initial Investment

Quality comes at a price. However, as with most technologies, costs are expected to decrease as the tech becomes more mainstream.

Training and Skill Development

As the equipment is highly specialized, there’s a need for skilled operators. Investing in training programs and workshops is the way forward.

The Future of CNC Side Skin Roll Forming in Car Assembly

Incorporating Green Technologies

How can CNC roll-forming equipment adapt and evolve as the world approaches sustainability?

The Role of Artificial Intelligence

AI is set to play a more significant role in optimizing and enhancing the CNC roll-forming process.

FAQs

How does CNC Side Skin Roll Forming Equipment differ from traditional roll-forming machines?

CNC roll-forming machines offer enhanced precision, consistency, and flexibility due to their computer-controlled operations, while conventional devices rely more on manual settings and adjustments.

How does this equipment impact the overall quality of cars?

Ensuring consistent and precise shaping of the car's side skins significantly enhances the vehicle’s aerodynamics, aesthetics, and structural integrity.

Are there any limitations to using CNC Side Skin Roll Forming Equipment?

The primary rule is the initial investment and the need for specialized training. However, the long-term benefits often outweigh these challenges.

What materials can be used with this equipment?

Most CNC roll-forming machines are versatile, handling various materials, including different grades of steel and aluminum.

Can CNC roll-forming equipment be used for other vehicle components?

Yes, while it's specialized for side skins, it can be used for other vehicle components with the proper adjustments and molds.

How has AI impacted CNC roll-forming processes?

AI introduces predictive analysis and real-time adjustments, leading to optimized operations and reduced errors.

Conclusion

The CNC Side Skin Roll Forming Equipment is a game-changer in car assembly lines. Its precision, efficiency, and adaptability make it an indispensable tool for modern car manufacturers. As technology advances, we can only anticipate even greater revolutions in this sector, with CNC roll-forming equipment leading the charge.